Deck floor forming machine

Decking floor production roll forming line speeds up to 25m/min, it is possible to produce various profiles through add quick-change unit. The whole line can be controlled by remote controller, integral guard was covered on the machine, which complying with European Unions safety standards and has been passed CE.

- Working flow

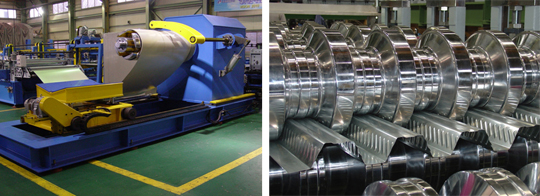

De-coiling→Guiding and feeding→Roll forming→Cut to length →Run out table

- Technical parameter

| Item | Parameter | |

|---|---|---|

| Suitable material | Type | GI, PPGI |

| Thickness | 0.4-0.8 (mm) | |

| Machine materia | Active shaft | No. 45 steel tempered |

| Roller | No. 45 steel chrome plated | |

| Cutting blade | Cr12 quenched | |

| Power requirement | Type | 80V/3PH/50HZCustomized |

| Main motor | 3kw | |

| Hydraulic | 2.2kw | |

| Hydraulic cantilever decoiler | Type | Hydraulic automatic |

| Max capacity | 2000kgs | |

| Suitable OD | 1200mm | |

| Suitable ID | 508/610mm | |

| Max width | 300mm | |

| Motor power | 2.2kw | |

| Hydraulic power | 2.2kw | |

| Forming speed (Excludes cutting & punching) | 20-25m/min | |

| Forming stand | About 14 group | |

| Transmission | Chain,sprocket | |

| Type of cutting | Length-set cutting | |

| Control system | Mitsubishi PLC& transducer | |

Deck Floor Forming Machine for Show:

- PU Sandwich Panel Line

- Roll Forming Machines

- Sandwich Panel Line

- 3D Wire Panel Line